System-One (SO-2A)

- Depositer

About the System-One

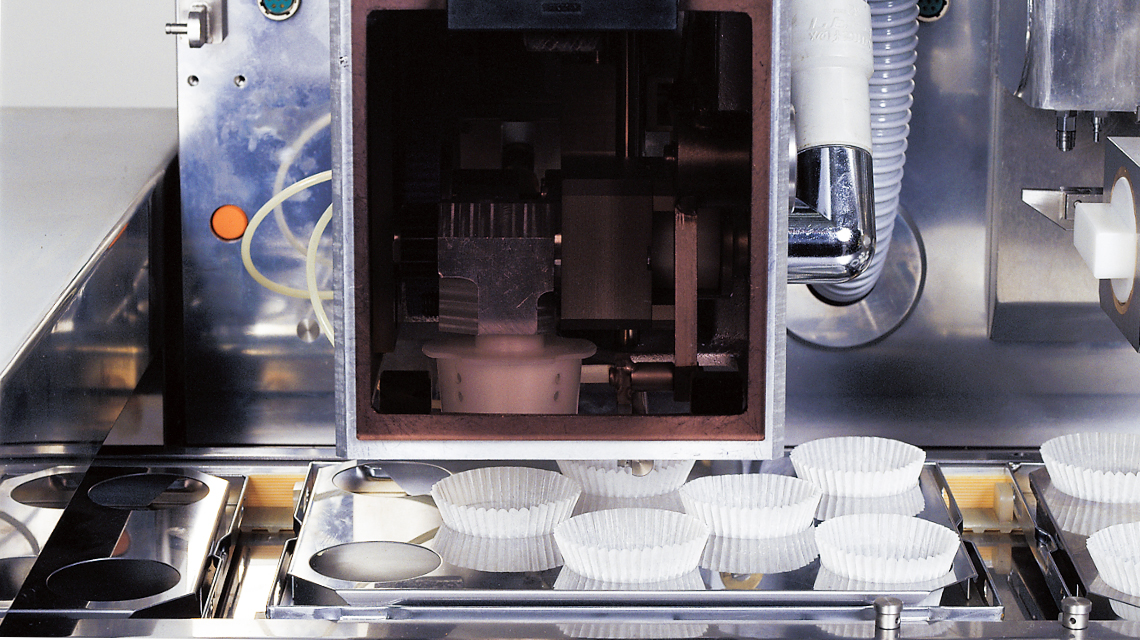

The System-One is a compact depositor that can easily deposit and shape batter for cupcakes and tarts. The machine comes with three heads that can be switched around depending on the product.

Product Information

Production Processes

Tarts

-

① Depositor

-

② Heat press

-

③ Filling depositor

Cupcakes

-

① Cup dispenser

-

② Batter depositor

-

③ Topping

Cupcake finish (mont blanc)

-

① Syrup injector

-

② Cream depositor

-

③ Chestnut paste depositor

Manju

-

① Batter depositor

-

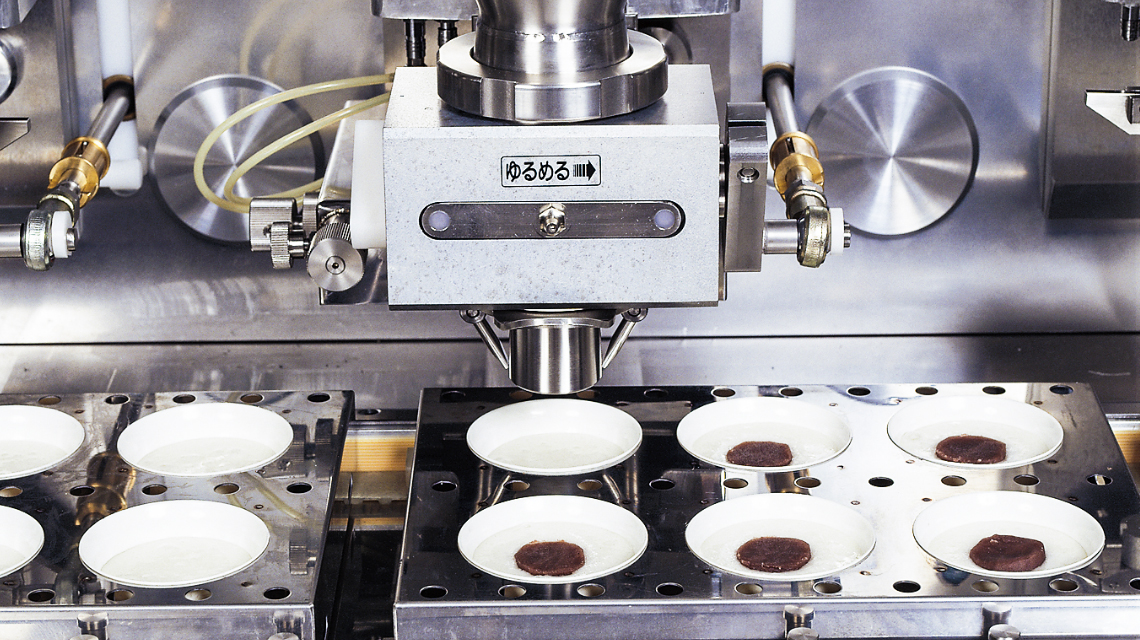

② Filling depositor

-

③ Batter depositor

Features

1. Easy changeover of products

The machine works with sheet pans, various other machines, and nozzles, and the head parts are lightweight. These can be easily switched around depending on the product.

2. Compact machine that does not take up much space

The dimensions of the machine is 2 meters in width and 1 meter in depth. It is compact and does not take up much space.

3. Incorporate in a production line

Combine this machine with a tunnel oven or tunnel steamer to build an integrated production line.

Production Capacity

Max. 2,000 rotations/hour

Food and confectionery that can be produced with the System-One

-

Cream puffs

-

tarts

-

bouchees

-

financiers

-

cupcakes

-

cookies

-

softmoon cake

-

steamed cakes

Product Video

Case studies of customers

who use the System-One

Proposing recipes

using the System-One

Look for another depositor

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.