Tunnel Oven (STO,SBOS)

- Oven

About the Tunnel Oven

The Tunnel Oven is suitable for mass production due to its efficient baking.

We have three feeding types: caterpillar type, steel belt type, and net type.

Tunnel Oven ECO BAKE

The "ECO BAKE" series has been released since June 2023.

This is an ecological and economical tunnel oven that contributes to reducing CO2 emissions, energy conservation, and running costs.

Benefits of the Tunnel Oven

Product Information

Lineup

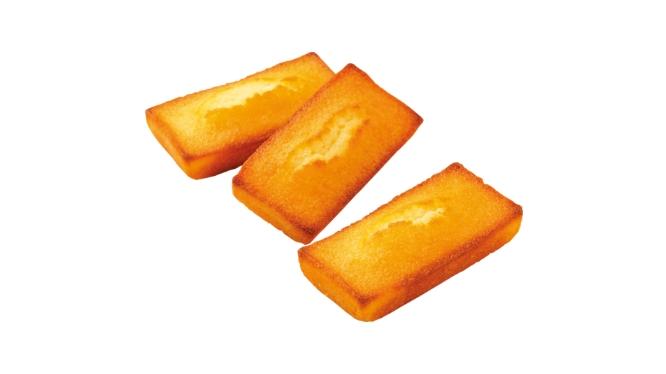

Caterpillar Type Oven: STOPut sheet pans and mold trays on the caterpillar to bake cream puffs, financiers, tarts, and base sponge cakes. It is easy to switch products and thus suitable for producing various kinds of products. It is also possible to create lines before and after this machine.

Steel Belt Oven: SBOS

Deposit batter directly on the steel belt to bake cream puffs, bouchees, sheet cake, langue de chat, cookies, sables, and manju. The productivity is very high and the machine is perfect for full automation.

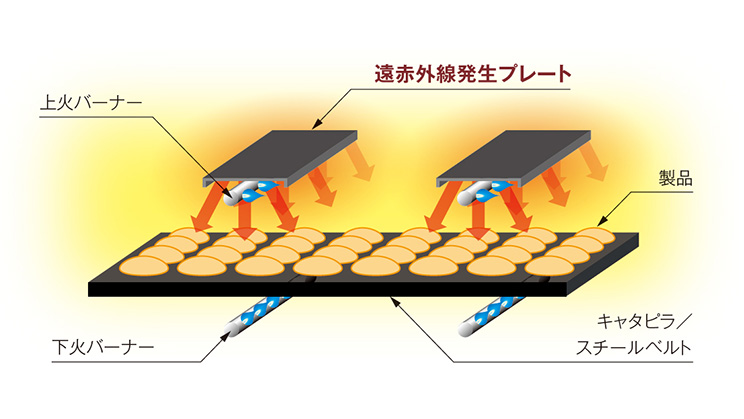

Features

1. The unique burners can control the amount of heat from low to high, making it suitable for a variety of confectionery from sponge cakes to cookies.

2. Far-infrared plates are effective in preventing uneven baking, cooking through, and reducing baking time.

3. The machine is durable and has a heat-resistant structure.

4. The system puts importance on safety.

5. Heat source options include gas, electric, or combination use of gas and electric.

※The gas tunnel oven can be equipped with a Superheated Steam Unit "Heat Plus'' as an option.

Food and confectionery that can be produced with the Heat Plus

-

Cream puffs

-

Tarts

-

Bouchees

-

Roll Cake

-

Financiers

-

Cupcakes

-

Baked Manju

-

Sheet Cake

-

Cookies

-

Langue de chat

-

Sables

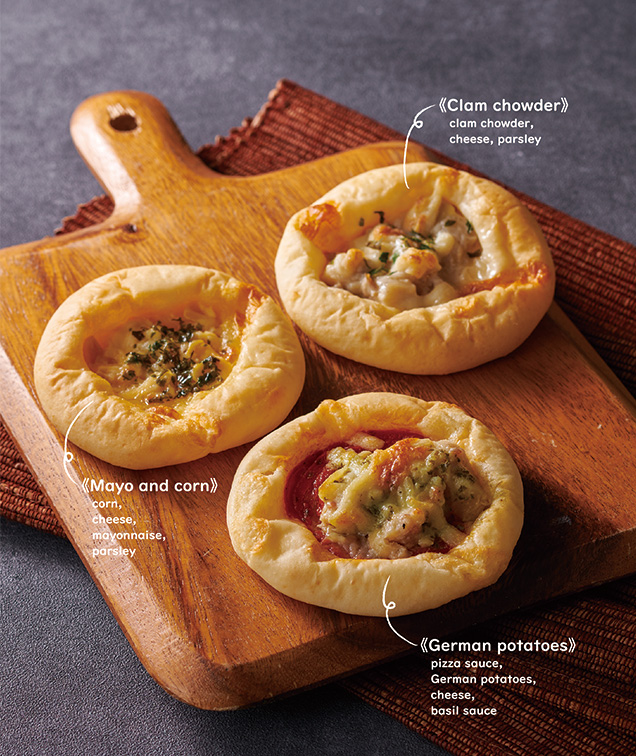

Case studies of customers

who use the Tunnel Oven

Proposing recipes

using the Tunnel Oven

Look for another tunnel oven or integrated production line

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.

TOP