Double-decked Tunnel Oven (STO-W)

- Oven

About the Tunnel Oven

The Double-decked Tunnel Oven has two tunnels that are perfect for an efficient production line. The machine maintains the same high-quality baking of the regular tunnel oven while achieving high productivity.

Benefits of the Double-decked Tunnel Oven

Product Information

Features

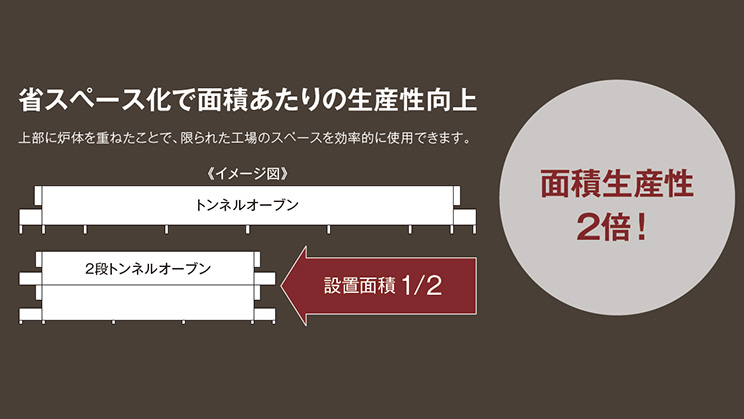

1. Double the area of production

The limited space in your factory is efficiently used with the Double-decked Tunnel Oven.

2. Bake different products per deck

One Double-decked Tunnel Oven can bake products that have different requirements as well as the same product and products that require to be baked twice. It is a versatile machine that can meet your ever-changing production needs.

Features

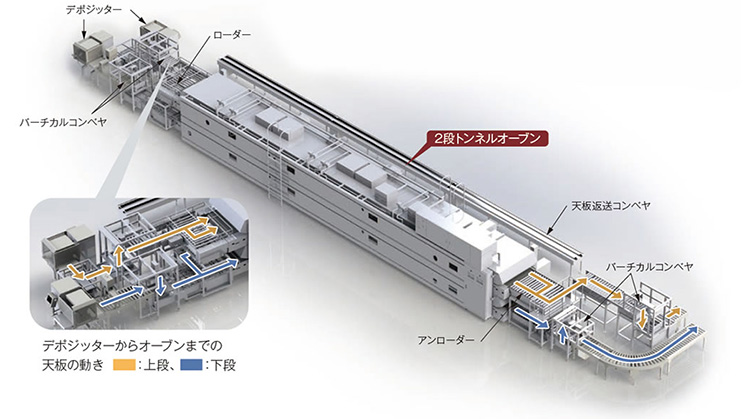

3. Incorporate it in a fully automated line for more efficiency

Combine the Double-decked Tunnel Oven with a depositor and other machines to build an efficient fully automated line.

Options

Superheated Steam Unit Heat Plus

Food and confectionery that can be produced with the tunnel oven

-

Cream puffs

-

tarts

-

bouchees

-

roll cake

-

financiers

-

cupcakes

-

baked manju

-

sheet cake,

-

cookies

-

langue de chat

-

sables

Case studies of customers

who use the Double-decked Tunnel Oven

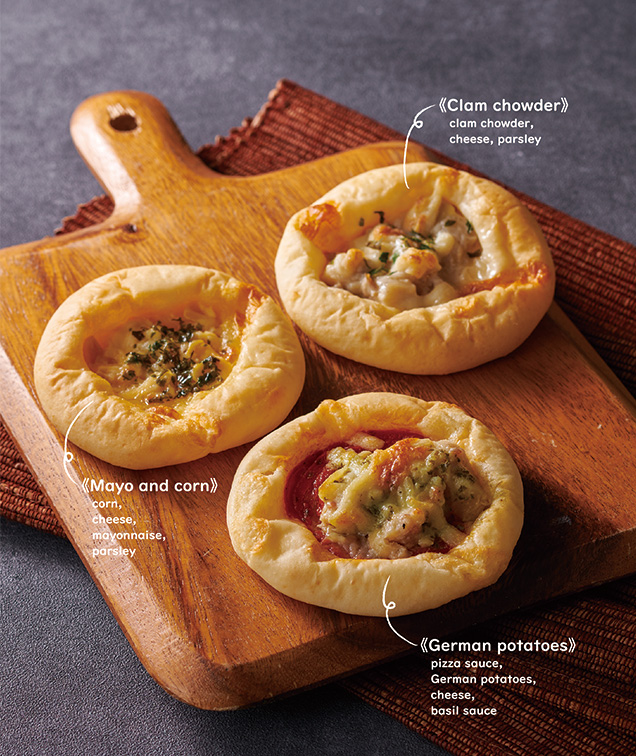

Proposing recipes

using the Double-decked Tunnel Oven

Look for another tunnel oven or integrated production line

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.