Universal Depoly (UD)

- Depositer

About the Universal Depoly

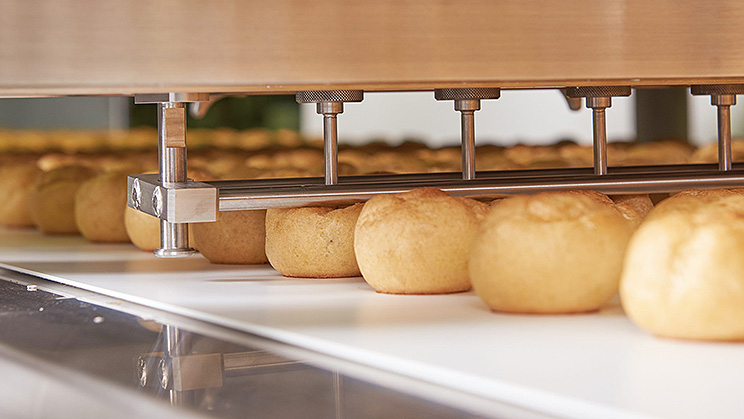

The Universal Depoly is a depositor to be combined with a tunnel oven or tunnel steamer to build an integrated production line. It can also be used for depositing batter or filling, and finishing.

Product Information

Features

1. A suitable depositing mechanism can be selected.

・Piston type depositor

・Outwards rotating rotor type depositor

・Three roller type depositor

2. Due to our unique control method, there is less vibration than usual, achieving highly accurate depositing.

Features

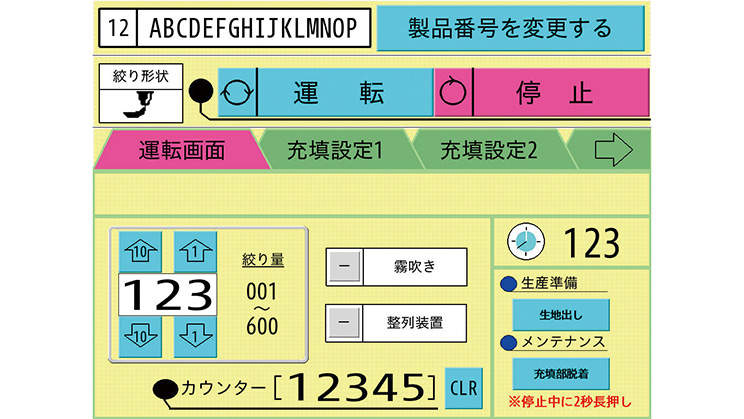

3. The touch panel screen allows you to easily change products and settings.

4. Safety covers with an interlocking function and safety guards inside the hopper protect operators.

5. There is an opening of 300 mm from the floor to the machine, making it easy to clean below the machine.

Production Capacity

Max. 2,100 rotations/hour

Food and confectionery that can be produced with the Universal Depoly

-

Cream puffs

-

tarts

-

bouchees

-

roll cake

-

financiers

-

pudding

-

cupcakes

-

decoration

Product Video

Case studies of customers

who use the Universal Depoly

Proposing recipes

using the Universal Depoly

Look for another depositor

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.