Case Study

- Depositer

- Sheet cake・castilla

ZENCA

ZENCA, located in Tokorozawa City, Saitama Prefecture, is a western confectionery manufacturer who has been growing, with B2B business forming their main pillar.

With production of small volumes of various products by hand being the strength that ZENCA has fostered since its establishment, ZENCA manufactures a wide range of professional-use cakes and baked goods in frozen form as national brand products. ZENCA also handles many OEM products for places like major hotels, franchised coffee shops, and amusement parks. Additionally, ZENCA is also highly acclaimed and known nationwide as an ODM (original design manufacturer), which is to receive orders for products from development to manufacturing.

ZENCA handles approximately 100 kinds of professional-use national brand products. Its catalogues have a diverse range of products with whole cakes and sheet cakes as their core items. Furthermore, ZENCA takes orders for cutting sheet cakes anywhere from 30 cuts to 120 cuts.

Its factory manufactures about 40 kinds of products every day including products for other companies.

Location:1-64-2 Hayashi, Tokorozawa City, Saitama Prefecture

URL:https://zenca.jp/

Publication:MASDAC news September issue in 2023

System Depoly (SD2-1U45-O)

ZENCA adopted a System Depoly (outwards rotating rotor type depositor) in November 2022. It is mainly used for production of cheese cake. “We used to deposit batter by hand, and there were so many items that it was very tough. Since we adopted the depositor, the tasks became a lot easier. It’s also user-friendly, and we’re glad we’ve adopted it.” ZENCA produces about 300 plates of cheese cake a day. The System Depoly’s conveyor belt is used with a return movement function, allowing one operator to manufacture efficiently. “As we produce many kinds of products in a small volume, mass production and automation is a challenge for us, but we’d like to strive for adopting machines and saving labor.”

-

Cheese cake

-

Cheese cake in production

-

A dough lifting machine supplies the batter to the hopper.

-

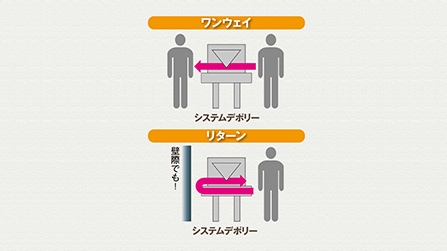

Characteristics of the conveyor belt

The conveyor belt has two movements: one way and return. The movement can be chosen depending on the site’s layout so that one operator can work on the line.

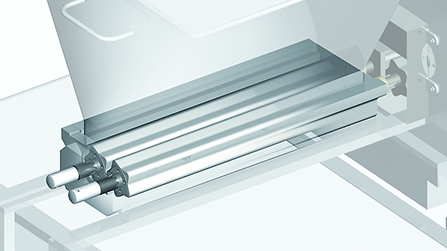

Outwards rotating rotor type depositor

・ There is less burden on the batter.

・ It can deposit batter consecutively, which means it can handle products such as sheet cakes, base sponge cakes, and pound cakes that require a lot of depositing.

・ Changing nozzles enables production of various kinds of items.

-

Production is possible even near a wall!

Reference

MASDAC NEWS trial version

Case studies are published in our PR magazine MASDAC NEWS delivered to users. In the magazine, we present various information related to sweets and food manufacturing, including an interview with our customers’ top management. Here, you can check out the trial version of the magazine. For periodical delivery of the MASDAC NEWS in a printed format, please send us a request via the following request form.

View the Trial Version (PDF)