Tart Forming Machine (TF)

- Depositer

About the Tart Forming Machine

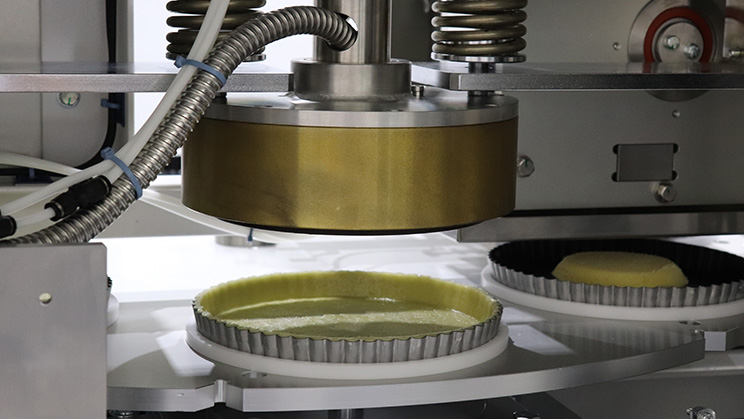

The Tart Forming Machine applies uniform pressure to press dough into the mold gently and without stress.

We offer both turntable-type and heat press only.

Product Information

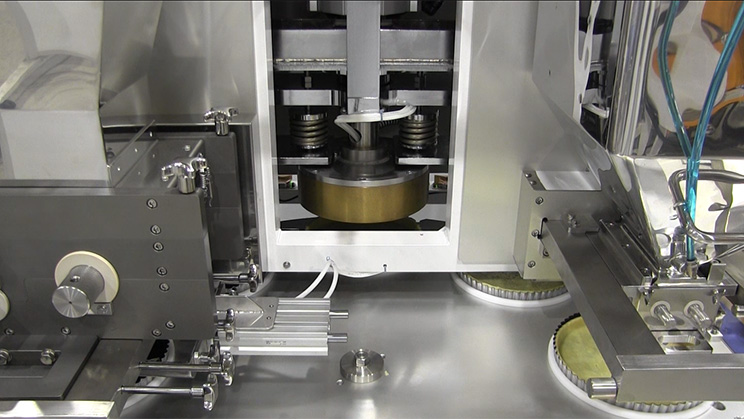

■Tart Forming Machine Turntable Type(TF-T)

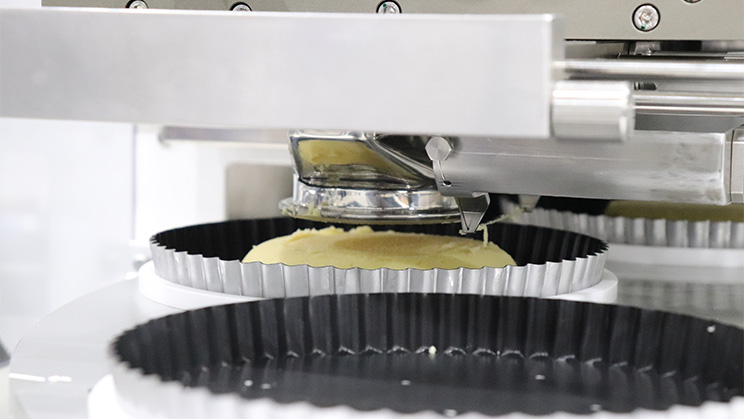

The machine features a unique three-roller depositing mechanism that allows for precise adjustments while preserving the dough’s integrity, applying no unnecessary force.

The heat press ensures consistent pressure, producing beautifully shaped tarts while maintaining efficient production.

It accommodates both round and wavy tarts with diameters ranging from 150mm to 210mm.

With this machine, basic tart production can be completed with ease.

Tart Forming Machine Turntable Type Production Processes

-

Turntable Type

-

1. Depositing dough

-

2. Heat press

-

3. Depositing filling

■Tart Forming Machine Heat Press only(TF-H)

This machine is specifically designed for the heat press process used to mold tart bases.

Its compact design saves space while automating the labor-intensive tart molding process, significantly improving efficiency.

It accommodates both round and wavy tarts with diameters ranging from 80mm to 240mm.

Tart Forming Machine Heat Press only Production Processes

-

1. Place the dough into the mold and set it in the machine.

-

2. Press the start button with both hands.

-

3. Heat press

-

4. The mold returns to its original position.

Food and confectionery that can be produced with the Tart Forming Machine

-

Tart

Product Video

Proposing recipes

using the Tart Forming Machine

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.

TOP