Depoly (HD)

- Depositer

About the Depoly

This piston-type depositing machine offers high-precision deposit in a compact, high-performance design.

Available in both tabletop and stand models, it operates efficiently regardless of dough/batter viscosity, making it suitable for a wide range of applications.

Despite being a single-row machine, it delivers an impressive production capacity of up to 3,600 cycles per hour.

Its simple, space-saving design ensures easy integration into any workspace.

With a foot pedal operation, it allows for effortless use by operators of all skill levels.

Product Information

Lineup

Depoly - TabletopType (HD-T)

Designed for use on a stand.

Depoly - Stand Type (HD-S)

Operates independently without the need for a stand.

Features

1. High Depositing Accuracy

This machine ensures precise and consistent dispensing, maintaining a steady fill volume regardless of dough/batter viscosity.

The fill amount can be finely adjusted, and the wide range of settings makes it suitable for various applications, from batter dispensing to filling.

Features

2. Easy Product Changes & Assembly

With fewer parts and a lightweight design, disassembly and reassembly for cleaning or switching nozzles and filling components can be done quickly and without tools.

This makes product changeovers smooth and efficient.

Features

3. Combination Examples

Despite being a single-row machine, it offers a high production capacity of up to 3,600 cycles per hour and can be seamlessly integrated with other machines.

Combination Example 1: Depoly x Dorayaki Machine

Features

3. Combination Example

Combination Example 2: Depoly x Box Steamer

Food and confectionery that can be produced with the Depoly

-

Cream puffs

-

Bouchees

-

Dorayaki(Depositing filling)

-

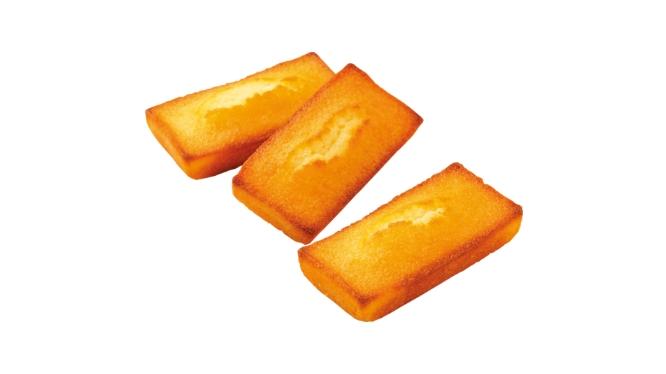

Financiers

-

Steam cake

-

Cupcake

Product Video

For inquiries about the Depoly, please contact us at the address below.

- Contact information

- MASDAC Co., Ltd

- info@newwww.masdac.co.jp

Proposing recipes

using the Depoly

Adoption flow

We utilize our experience cultivated as a confectionery machine manufacturer for more than 60 years to entirely support our customers from before ordering to after the delivery.

-

①

Meetings and

propositionsWe hold meetings to discuss what products a customer is looking to produce and provide various propositions.

-

②

Pre-test

Customers can actually use a machine in our Application Center and test using their own recipes before adoption.

-

③

Quote and

contractWe propose perfect machinery and equipment according to the test results.

-

④

Pre-shipment inspection

Our quality assurance staff conducts the final check before shipping the machinery.

-

⑤

Delivery and test run

We deliver the machinery to our customer’s factory, test run the machinery, and witness the first production on-site. We will handle each case responsibly until the machinery operates perfectly.

TOP